Building on our extensive experience in marine hoses for the oil and gas industry since 1998, HOHN GROUP has put its proven expertise, engineering and manufacturing capability into developing truly EN 1474:2 composite structure flexible cryogenic hoses to support the extremely challenging environment of offshore Creative Jettyless LNG transfer platform instead of Traditional Jet Transfer.

The Jettyless Transfer Composite Cryogenic Hose is available in diameters from 6 inch to 24 inch to meet the transfer rates required. Hose sections can be joined together using their flanged end fittings to form large strings of hose of the length required for any given projects or by ONE SINGLE LARGE LENGTH STRING Seperatedly as customized requirement, commonly single continuous large length string could be from 150 to 500.0 meters which saves operation time on installation. and our EASY-TO-REPAIR system could guarantee the hoses string continuous operation.

The future of LNG Energy transfer is growing FASTLY.

HOHN GROUP has successfully designed, fabricated, supplied many offshore terminals based-on single-point-mooring-floating-hoses or similar applications since 2010 to CNOOC and Type approved in 2016 by DNV.GL. The design and operational philosophies applicable to those terminals have also been applied to the design and implementation of the transfer solutions enabling offshore production units as well as fully weathervaning LNG SPM type offshore terminals. The technology for cryogenic fluid handling and regasification has now evolved to maturity for implementation in LNG offshore terminals that are expected to provide an economical and safe alternative to traditional methods of LNG transfer or in Jettyless Transfer applications(A jettyless transfer system is floating technology that enables safe and efficient transfer of fluids such as LNG, ammonia, bio fuels and CO2 (for carbon capture and storage) between a carrier and an offshore or onshore terminal without a jetty.).

HOHN GROUP is able to offer a complete LNG transfer hose system suitable for floating offshore production and re-gasification facilities as well as near shore terminals. All systems are based on the Composite Cryogenic Hose meeting EN 1474:2 2020, the one large bore hose truly suitable for offshore LNG transfer.

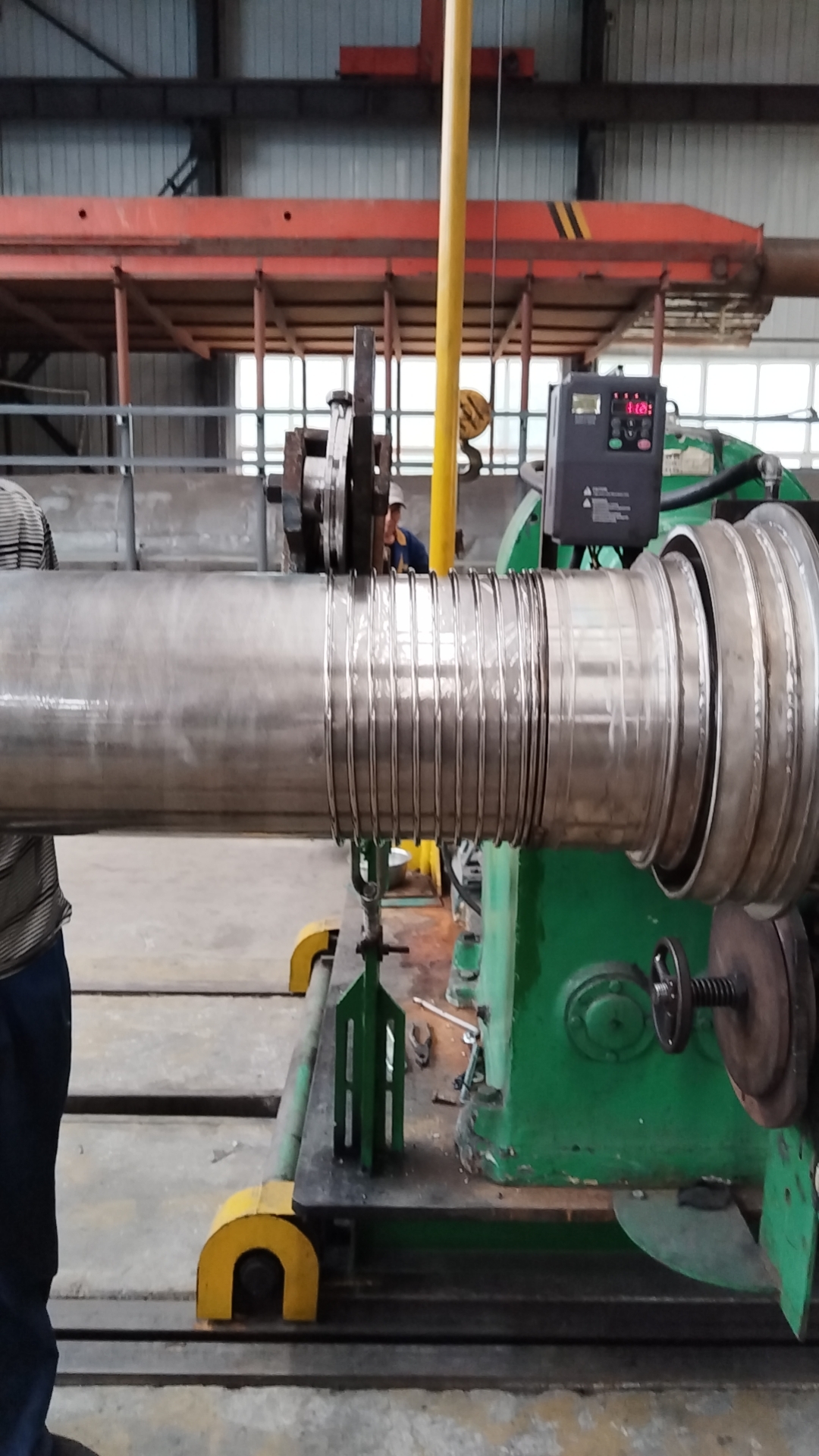

Main Production Process:

Inner layers is Stainless Steel 316 wrapping by automation:

Super high performance Cryogenic materials are used into the LNG hose:

Unique workmanship of special Thermal Insulation material keeps its high performance and high buoyancy >20% or customized under -196°C even -200 temperature.

High tensile strength High working pressure capability and flexibility throughout the working temperatures Transfer high product volumes whilst remaining light weight

Insulation Properties Requirements: No frost on the outer cover; Customized insulation layers thickness to guarantee no frost, no frost is the minimum requirement, almost no leakage of temperature, no obvious temperature difference between the hose out cover and the outside;

The custom large bore aerial hose has been developed to meet the EN 1474-2 standard and can be used in a number of different cryogenic LNG transfer configurations, such as side by side transfer, tower transfer and in dynamic tandem configuration for transferring in more unforgiving sea conditions.

Design life time 10 or 15 years.

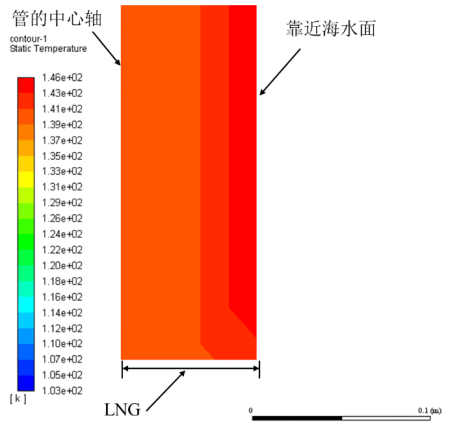

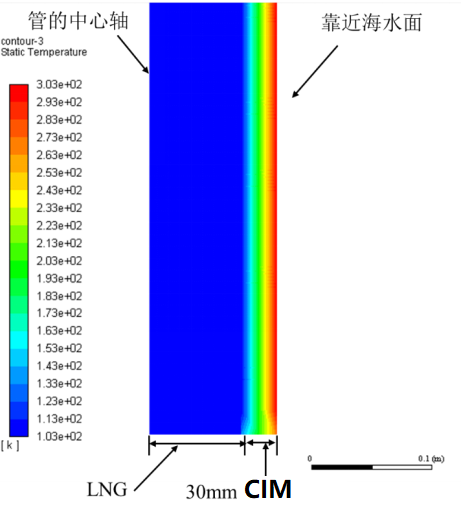

The below is a performance of our Customized insulation materials in the hose:

Figure 1 Without Customized insulation materials,纯LNG的出口附近的温度分布云图

Results analysis: As shown in Figure 1, assuming the convection heat transfer coefficient between the outer wall of the pipeline and the seawater is 150 W/m2·K, the temperature of the LNG at the pipeline outlet is between 141K and 146K (i.e., -132℃ to -127℃). The temperature of the LNG near the seawater is 146K (-127℃).

Figure 2 with Customized insulation materials(CIM) for the hose out cover,出口附近的温度云图

Result analysis: As shown in Figure 2, assuming the convection heat transfer coefficient between the pipeline outer wall and seawater is 150 W/m2·K, the temperature of the LNG at the pipeline outlet is basically the same as the inlet temperature, still 103 K (i.e., -170°C), which can meet the customer’s temperature requirements.

Leak Monitoring system with Distributed fiber optic monitoring system optional.

The Achilles’ Heel of the Energy Transition?”

Global LNG demand is skyrocketing—but what if Jettyless LNG floating transfer hoses are the weakest link in the supply chain? Between cryogenic failures, pirate threats in the Malacca Strait, and the lack of standardized emergency disconnect protocols, are we one catastrophic spill away from a regulatory crackdown that cripples the industry?

Welcome to contact our expert to help you!