The standard range of HOHN’s single and double carcass hoses is widely utilized on a variety of single point moorings (SPM) including CALM and SALM buoy terminals. Manufactured to the latest OCIMF 2009 certification, these hoses are the principal means for tanker loading and discharge operations offshore since the 1960’s. We are DNV.GL certificated on 2016 year.

HOHN is able to propose tailor made submarine hose string solutions to fit every customer need. All our marine hose are designed and manufactured according to GMPHOM 2009.

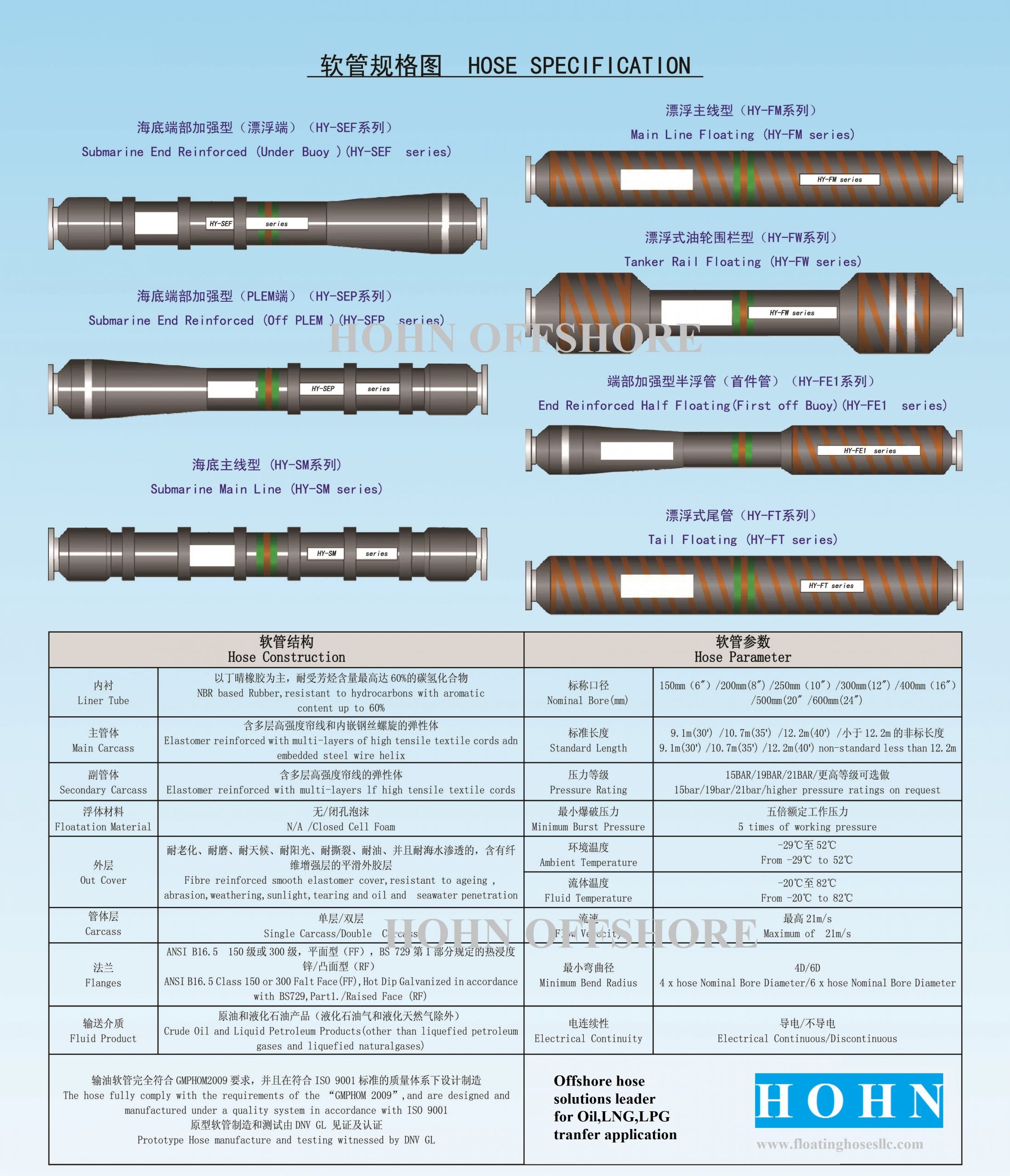

The configuration hereunder indicated is the most common hose string configuration. HOHN Offshore however, depending on each specific case, is able to propose a tailor made solutions to fit every customer need.

Double Carcass/DC Floating type

Our OCIMF 2009 Double Carcass hoses are built with two carcasses in order to prevent any possible leakage of product in the first carcass, which can be possibly detected by means of an high reliable mechanical leak detector, assuring the long lasting service life of the hose. The hoses are built with steel cords reinforcements (first carcass), helix steel body and polyester cords reinforcements (second carcass) with floating material (foam cell) in order to guarantee the correct reserve buoyancy, depending from the positions and the function they have within the hose string. They are made of multiple plies of high performance materials to resist to harsh marine environment conditions in long lasting applications.

General specifications:

- ID: from 6” to 24”or customized

- DOUBLE CARCASS CONSTRUCTION

- FLOATING

- Standard lining in NBR rubber suitable for crude oil and oil by products

- Standard Reinforcement:

- 1st carcass: Multiple plies of wire steel cord with one embedded helical body steel wire

- 2nd carcass: Multiple plies of textile wire cord reinforcement

- Cover in chloroprene black synthetic rubber resistant to oil, abrasion, sunlight or polyurethane suitable to heavy ware duty upon request

- Rated Working Pressure 15 or 19 or 21 bar

- Minimum burst pressure::

- 1st carcass: 75 or 95 or 105 bar

- 2nd carcass: 30 or 38 or 42 bar

- Built in fittings during manufacture

- Standard Flange type: ASME B 16.5 class 300 lb or 150 lb, WN FF or RF, different solutions upon request

- Standard Flange material: ASTM A105N / Hot dip galvanized (600 g/m2) or equivalent

- Standard Nipple material: ASTM A106N gr. A/B or equivalent

- Maximum flow velocity: max. 21 m/s

- Fluid Temperature range -20/+82°C

- Ambient Temperature range -29/+52°C

- Maximum Temporary Elongation 2.5%

- Maximum Permanent Elongation 0.7%

- Electrical: discontinuous or continuous upon request

Single Carcass/SC Floating type

Our OCIMF 2009 Single Carcass hoses, are built with one carcass (steel cords reinforcements and steel helix body) and floating material (foam cell) in order to guarantee a certain reserve buoyancy depending from the positions and the function they have within the hose string. They are made of multiple plies of high performance materials suitable to resist to harsh marine environment conditions in long lasting applications.

General specifications:

- ID: from 6” to 24”

- SINGLE CARCASS CONSTRUCTION

- FLOATING

- Standard lining in NBR rubber suitable for crude oil and oil by products

- Standard Reinforcement – Multiple plies of wire steel cord with one embedded helical body steel wire

- Cover in chloroprene black synthetic rubber resistant to oil, abrasion, sunlight; polyurethane available upon request

- Rated Working Pressure 15 or 19 or 21 bar

- Minimum burst pressure: 75 or 95 or 105 bar

- Built in fittings during manufacturing

- Standard Flange type: ASME B 16.5 class 300 lb or 150 lb, WN FF or RF, different solutions upon request

- Standard Flange material: ASTM A105N / Hot dip galvanized (600 g/m2) or equivalent

- Standard Nipple material: ASTM A106N gr. A/B or equivalent

- Maximum flow velocity: max. 21 m/s

- Fluid Temperature range -20/+82°C

- Ambient Temperature range -29/+52°C

- Maximum Temporary Elongation 2.5%

- Maximum Permanent Elongation 0.7%

- Electrical: discontinuous or continuous upon request

Feel free to contact us for a quotation or specific request of further information regarding GMPHOM 2009 hoses in cryogenic working environment: www.hoses.cc