Gas, and its liquefied form, presents a different challenge in as much as it needs to be transported at a temperature of (minus) -162°C.

Any LNG transfer solutions require specialized hoses to transfer LNG to re-gasification plants onshore or, as increasingly envisaged, offshore. This has led to several breakthroughs for safe, efficient transfer ,particularly to suit environments where the water may be too shallow for a ship to moor at a jetty, or where it may be too deep or too far offshore to build a jetty.

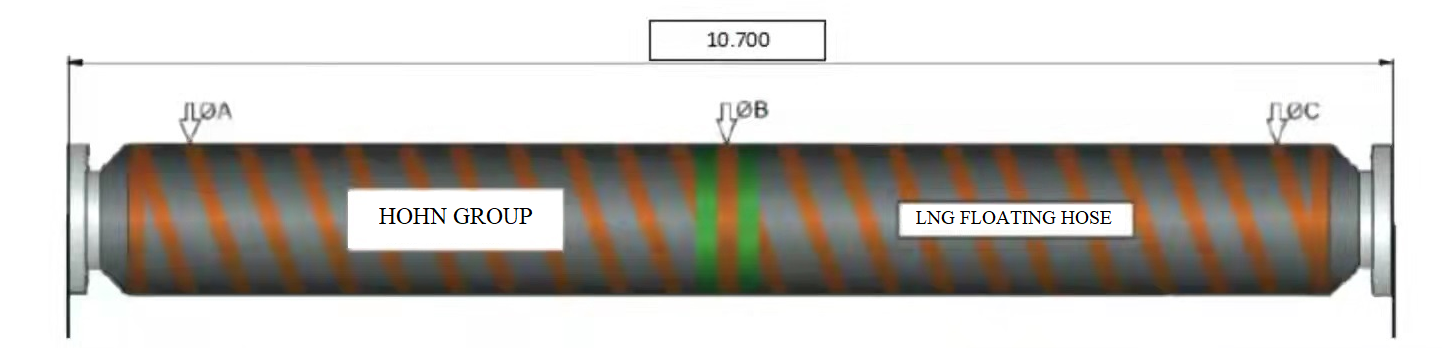

Cryogenic flexible floating hose technology, such as HOHN GROUP’s CryoGenicLine hose, provides a unique solution to make LNG transfer safer, more efficient, and less Capex-intense in a variety of locations. The new floating cryogenic hose comprises several key components, including an inner cryogenic hose, an outer protective hose, an efficient insulation layer, and an integrated leak monitoring system. The inner cryogenic hose has been created from the latest developments in composite hose technology, which is already renowned for its unrivalled flexibility.

Composite LNG hoses typically consist of multiple un-bonded, polymeric film and woven fabric layers, encapsulated between two stainless steel wire helices—one internal and one external. Essentially, the film layers provide a fluid-tight barrier to the conveyed product, with the mechanical strength of the hose coming from woven fabric layers. The number and arrangement of multiple polymeric film and woven fabric layers is specific to the hose size and applications.

Conformity: EN 1474-2; OCIMF; API 17K, API 17J or as required

Standard Dimensions(Diameter): From 6 to 24 inch or custom size as required

Insulation properties: No frost on the outer cover; Customized insulation layers thickness to guarantee no frost, no frost is the minimum requirement, almost no leakage of temperature, no obvious temperature difference between the hose out cover and the outside;

FLNG/Ship-to-Ship

Offshore operations are among those that can benefit most from cryogenic hose technology, both floating FLNG and FSRUs.

Moving LNG production to an offshore setting presents a uniquely difficult set of challenges for the offshore oil & gas industry, particularly when it comes to the design and construction of FLNGs. Not only do FLNG facilities need to maintain the highest levels of safety, but extraction and transfer of the LNG to tankers needs to continue uninterrupted in even the most demanding conditions of climate and current, often hundreds of miles away from land.

While loading arms are designed to handle both liquids and gases in a wide range of viscosities and temperatures, environmental constraints, such as tidal and wind conditions and the effect of earth movement, can have a significant effect on the performance of loading arms.

At the same time, the proximity of the FLNG and carrier necessary in this configuration—the distance between them can be as little at 5 m (16 ft)—has the potential to result in both operational issues and a higher risk of safety issues, with the worst case being a collision between the vessels. This is something which cannot be countenanced due to the remote nature of many FLNGs and the resulting lack in readily accessible proper repair equipment, components, and expertise—compounded by delays in transportation of the LNG and all the associated costs.

To address these issues, there has been a drive toward the employment of tandem offloading, with the two vessels situated one behind the other at approximately 100—150 m. This virtually eliminates the risk of collision and enhances the overall safety of the transfer process, allowing it to occur in even the most inhospitable conditions with waves of up to 10 m. This approach can also greatly simplify the processes of approach, berthing, and residence.

This approach is equally well suited to transfer between LNG carriers and FSRUs. Floating receiving and distribution terminals and coastal gas carriers are now an integral part of LNG activities and a crucial cog in the LNG supply chain. By using floating cryogenic hoses in tandem configuration, vessels can be moored as much as 300–500 m away from a storage unit. Again, this increased separation distance mitigates the risk of collision and ensures the safety of the vessels and crew and, moreover, the heavy-duty hose design reduces risk of damage to the hose during handling.

The flexibility and high flow rates achievable by cryogenic technology also makes it an ideal solution for ship-to-shore transfer. It increases the economic feasibility of power generation, terminal, and marine bunkering projects located away from existing infrastructure – particularly in areas where jetty-based transfer would be unfeasible thanks to harsh conditions or environmental concerns.

HOHN GROUP’s cryogenic hose-in-hose technology can negate the need for fixed onshore infrastructures; a concrete platform onshore combined with CryoGenicLine hose transfer solutions offers an alternative that can be up to 80% more cost-effective for locations where fixed onshore infrastructure would be prohibitive.

Collaborations with Jettyless innovative worldwide partners demonstrate how ship-to-shore operations using cryogenic floating hoses can be further enhanced, and offer increased flexibility and a choice of transfer options. Floating transfer terminals or barges can be connected to the shore using CryoGeniLline hoses, which can then easily connect with a vessel using a transfer system on a barge. These solutions can be built, outfitted, and commissioned off-site in parallel with relatively light civil engineering activity, reducing the overall timescale from contract award to first gas.

As a self-contained mobile unit, a floating barge or transfer unit can be readily adapted for future and alternative deployment in the event of local changes or a desire to move location entirely, and individual components can be up- or down scaled depending on requirements. A floating solution also allows for refuge to be sought in a safe harbor during storms or hurricanes, deep maintenance to be undertaken at a shipyard, integration with a variety of LNG carrier mooring configurations, and the flexibility to support future, alternative applications. Moreover, the barge is also only used when transfer is underway, minimizing impact on the environment.

In conclusion, cryogenic hoses in floating configurations unlock new opportunities for LNG transfer both at sea and in near-shore environments, reducing risk of safety incidents and downtime, and lowering handling procedure time by as much as 60% in some instances. It is perhaps unsurprising then that the prognosis for this technology is good.

Mr Qiang.Gao, director at China HOH GROUP Oil and Marine, is an expert in crude oil offloading solutions and LNG offshore transfer and has worked in the oil and marine field for more than 20 years. He handles Oil & Marine’s complete product range of oil and gas transfer systems, including solutions for floating LNG and small-scale LNG applications. At HOHN, Gao has been responsible for the design and qualification of flexible bonded hoses for offshore crude oil transfer (oil offloading lines, reel systems) and LNG transfer. For He may be contacted at gq@hoses.cc