SHANDONG HOHN GROUP: DREDGING FLOATING HOSES AND PIPE AND FLOATS EXPERT SINCE 1988! DEDICATED IN OFFSHORE CONSTRUCTION;DREDGING;MARINE SERVICE.

Dredging projects are often classified into three categories: capital, that is, for new infrastructure, maintenance, or remedial (environmental) projects.

Ports and estuaries are under constant threat of siltation. Tidal movements deposit sand and silt from the sea in port basins and waterways. Rivers also carry sediment in their flows, which tends to settle in deltas. Due to these natural phenomena, the water depth gradually decreases. In order to safeguard a constant navigable depth, maintenance dredging is required.

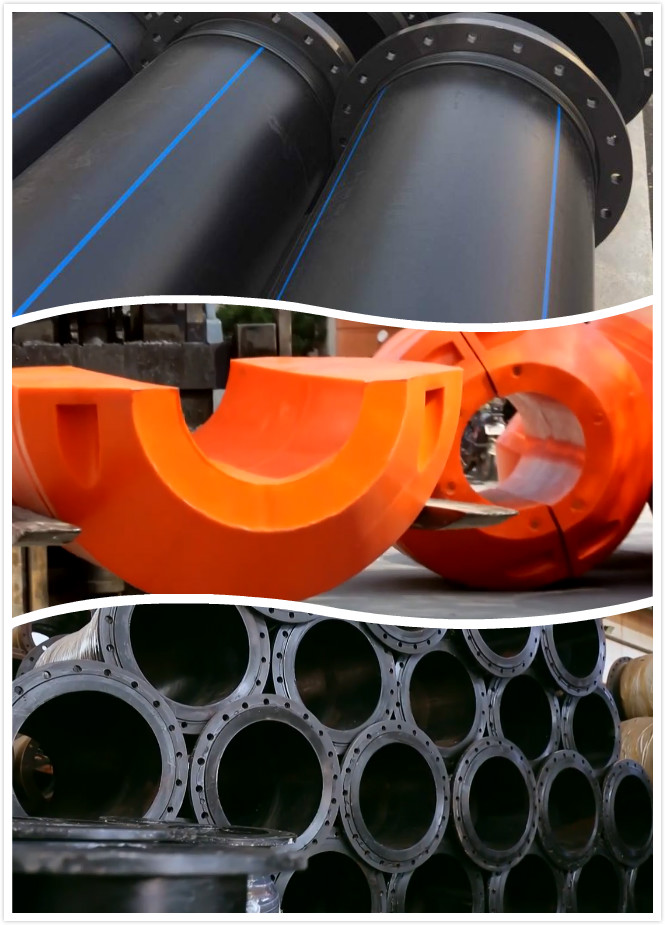

Growing global trades has led to an increase in maritime transport. In order to accommodate this growth in international shipping and ever larger vessels, new ports are being constructed around the world and existing port infrastructure is being expanded. Dredging activities for port construction and expansion include the creation of access channels, berthing places and turning basins, reclaiming land for yard and terminal activities, and the deepening and widening of existing waterways. HOHN Group Pipe and Plastic Floats Dredge line components is designed and produced for Port or Harbour Construction Dredging.

HOHN Dredge Pipe Floats/Floaters are composed by two halves, the inside diameter of pipe floats will be same (or slight smaller) to HDPE/Steel dredge pipe’s outer diameter, so the Dredge Pipe Floats can be fixed via bolts and nuts tightly on the HDPE/Steel dredge pipe or the hoses without slipping. Two halves of pipe floats are connected by bolts/nuts that are made by galvanized steel grade material.

Dredge HDPE pipe/Steel Pipe for the above plastic floaters are preferred in modern dredging works cases.

In dredging works, when conveying solid materials with sharp angles, ordinary rubber hoses without armor protection are easily damaged inside under high pressure.

For the steel ring armored floating hoses, as the rubber and steel rings is not synchronized, it result in grooves.

HOHN Group own-patented full armored rubber discharge hoses solves this problem as huge market desires, our full armoured discharge hoses could dredge above 10 million cubic meters sediments or other dredging medium and easy to repair. It is enjoying more and more prefer in the CSD dredger dredging works.

For more details please visit SHANDONG HOHN Group official website:

www.floatinghosesllc.com