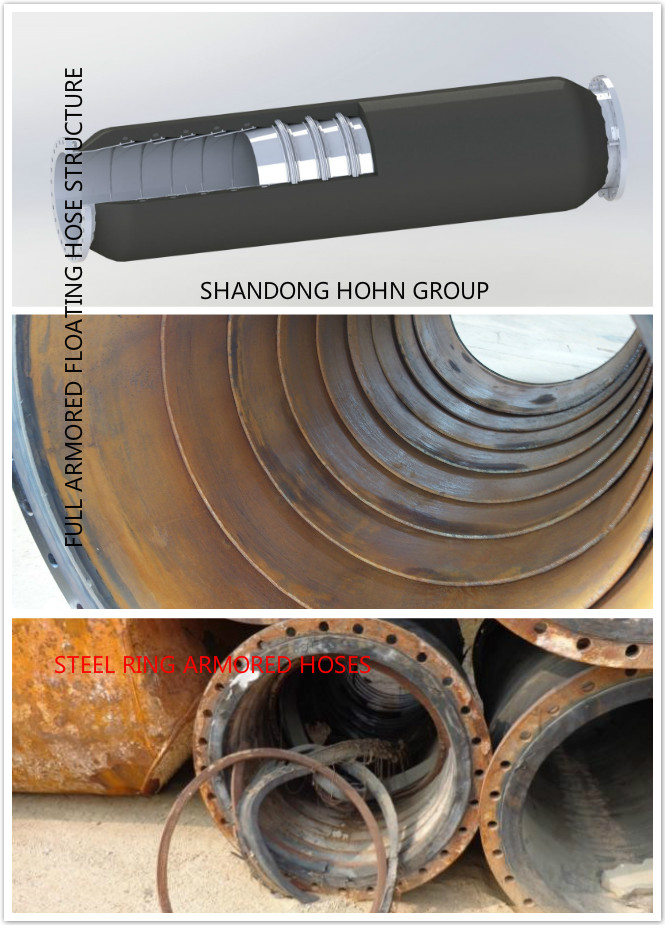

HOHN GROUP Full armored rubber floating hoses advantage introduction:

HOHN Group Inner full armored rubber hoses for dredging: It is composed of metal cone pipe, rubber layers, steel wire, rubber outer coating and flanges. The structure type is that multiple cone pipes are nested in sequence. After being combined with the rubber layer, Multi-strand steel wires are tied and fastened together, and finally covered with a rubber outer coating.

In dredging works, when conveying solid materials with sharp angles, ordinary rubber self-floating hoses are easily damaged inside.

For the steel ring armored floating hoses, as the rubber and steel rings is not synchronized, it result in grooves.

HOHN Group Full armoured rubber floating hoses are equipped with wear-resisting metal cone sleeves through the rubber hoses, so the solid dredging sediments (like Coral reef, medium coarse sand, heavy stone etc) and rubber hoses do not contact and wear synchronously, so as to achieve the effects of wear-resisting, bending cushioning and wind wave resistance. It can bend more than 30 degrees. In the working conditions (Midium containing sand less than 30%) the buoyancy is above 25% of the hose outer diameter.

Flanges could be customized according to your requirements.

HOHN GROUP Full armored rubber floating hoses Specifications:

| ID mm | PCD mm | Hole Number | Hole ID | Length mm |

| 600.0 | 760 | 18 | 27 | 5800/11800 |

| 650.0 | 780 | 24 | 27 | 5800/11800 |

| 700.0 | 840 | 24 | 27 | 5800/11800 |

| 750.0 | 920 | 30 | 28 | 5800/11800 |

| 800.0 | 970 | 32 | 30 | 5800/11800 |

| 850.0 | 1020 | 24 | 32 | 5800/11800 |

| 900.0 | 1110 | 28 | 39 | 5800/11800 |

| 1000.0 | 1210 | 28 | 45 | 5800/11800 |

Have a look at the HOHN Full armored floating hoses structure compared with the steel ring armoured floating hoses:

HOHN Group full armored floating hoses makes the inner wall of rubber hose not exposed, and partial grooves after wearing wont happen.

Existing problems for steel ring armored floating hoses:

1 steel ring off as the boding strength is not enough between the ring and rubber

2 Resulting grooves

3 Deformation and blockage of the ring

So if you need high quality armored floating hoses, choose it and make it right.